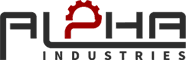

Press Brake Frame Rigidity: The Structural Core of Precision Bending

In sheet metal bending, press brake frame rigidity is the fundamental factor that determines long-term accuracy, machine stability, and production reliability. While control systems and tooling influence bending results, the mechanical structure of the press brake ultimately defines how consistently those parameters can be maintained.

A press brake with insufficient frame rigidity will experience elastic deformation under load, leading to angle deviation, uneven bending results, and accelerated mechanical wear. Alpha designs press brake frames with reinforced structures engineered to maintain geometric stability under continuous high-tonnage operation.

Why Frame Rigidity Is Critical in Press Brake Performance

During bending, the press brake frame is subjected to extreme vertical and torsional forces. These forces increase significantly when processing:

-

Long workpieces

-

Thick plates

-

High-strength materials

-

Full-length bending operations

If the frame lacks sufficient rigidity, deformation occurs not only at the ram and table, but throughout the machine structure. This deformation directly affects bending accuracy and repeatability.

A rigid press brake frame ensures that bending force is transmitted efficiently and predictably, maintaining consistent bending angles across the entire working length.

Structural Design Factors Affecting Press Brake Rigidity

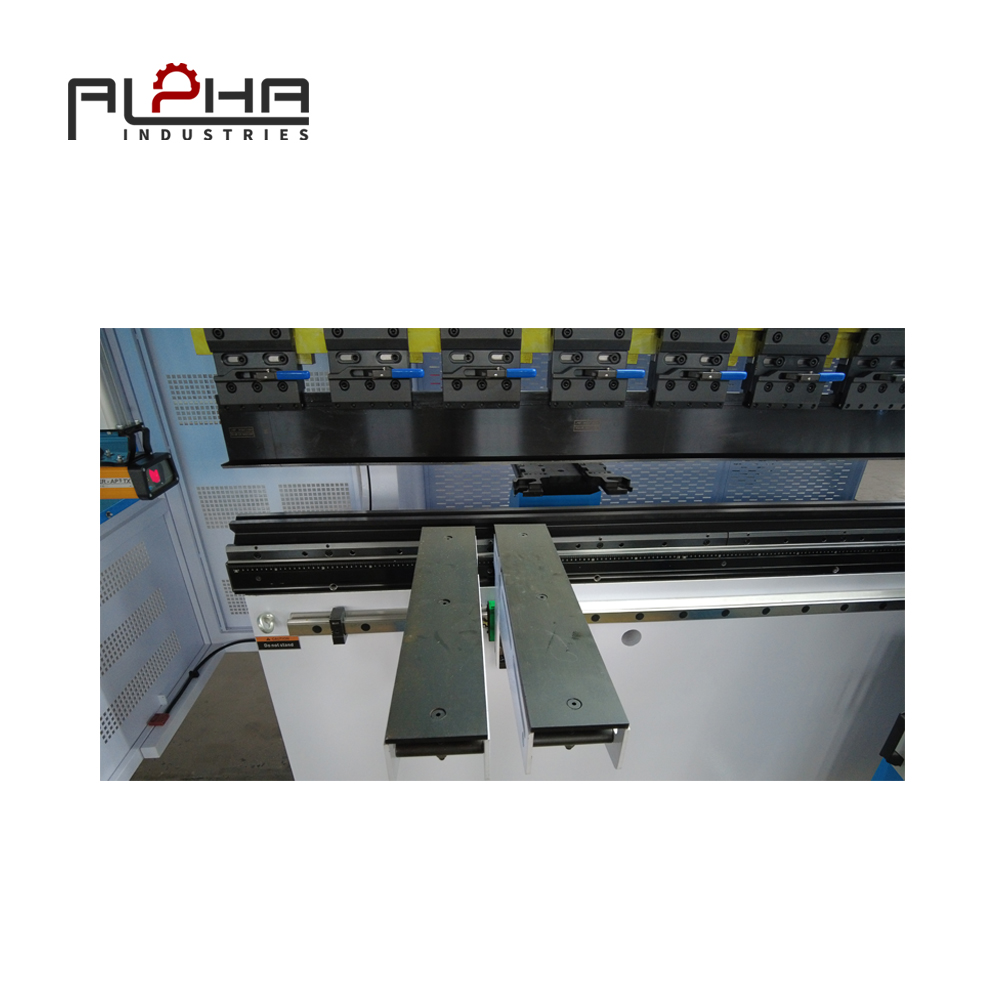

High-Strength Steel Frame Construction

The foundation of frame rigidity begins with material selection. High-quality press brakes use high-tensile steel plates with controlled chemical composition and mechanical properties.

Alpha press brake frames are manufactured using thick, high-strength steel plates to ensure optimal resistance to bending and torsional stress.

Integrated Welding and Stress Relief Treatment

Frame welding quality has a direct impact on long-term structural stability. Improper welding introduces internal stress that can lead to deformation over time.

Alpha press brake frames undergo controlled welding procedures followed by thermal stress relief treatment. This process eliminates residual stress and ensures structural stability throughout the machine’s service life.

Optimized Frame Geometry

Frame rigidity is not only determined by material thickness but also by structural geometry. Reinforced side frames, optimized cross-section design, and load-balanced structures improve stiffness without unnecessary weight increase.

Finite element analysis is applied during the design stage to identify high-stress zones and optimize structural reinforcement.

Frame Rigidity and Bending Accuracy Relationship

A rigid press brake frame directly contributes to:

-

Stable ram parallelism

-

Uniform force distribution along the bending length

-

Reduced angular deviation

-

Improved repeatability in batch production

Without sufficient rigidity, even advanced control systems cannot compensate for structural instability. Mechanical precision must exist before electronic accuracy can be effective.

Long-Term Stability and Machine Service Life

Frame rigidity also plays a critical role in machine durability. Structural deformation accelerates wear on guideways, cylinders, and transmission components.

A rigid frame ensures:

-

Reduced mechanical fatigue

-

Extended component service life

-

Lower maintenance frequency

-

Stable performance over years of operation

Alpha press brakes are engineered to maintain structural integrity under continuous industrial workloads.

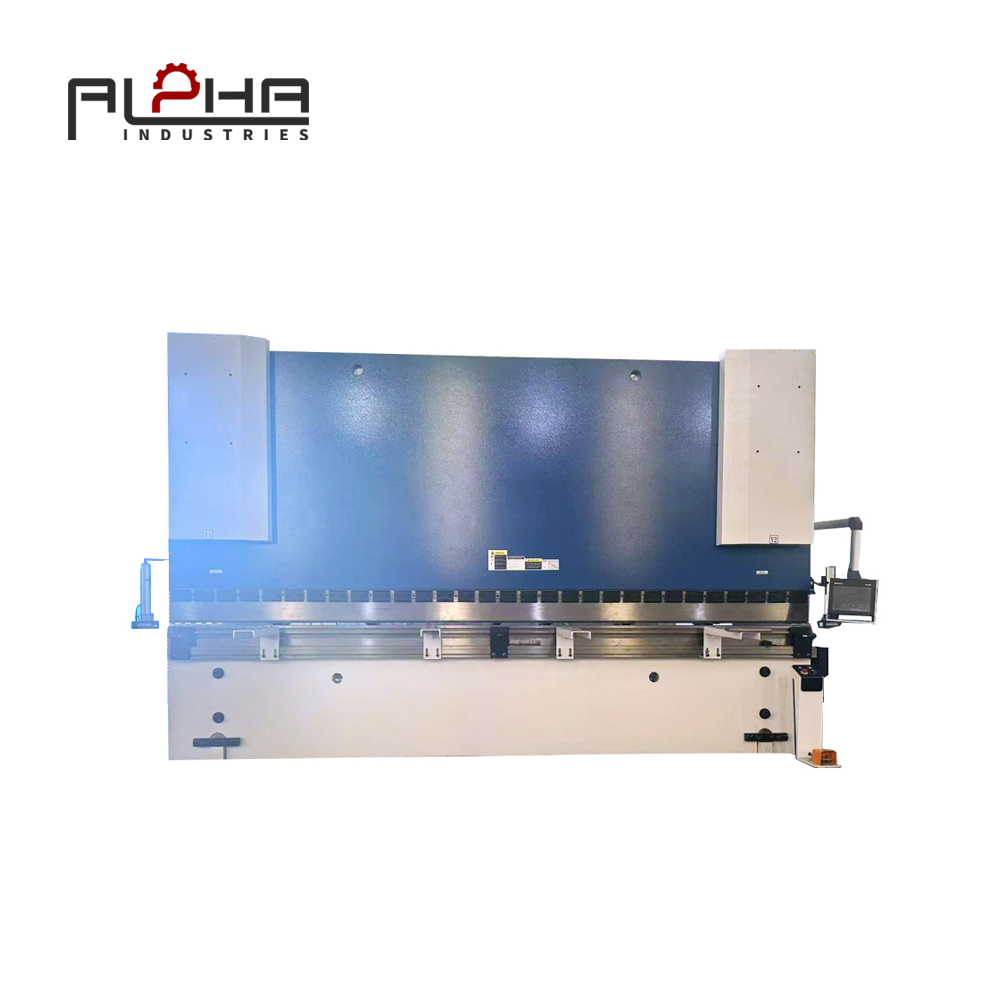

Compatibility with High-Precision Systems

High frame rigidity provides a stable platform for advanced technologies such as:

-

Hydraulic deflection compensation

-

Servo-controlled backgauge systems

-

High-precision ram guidance

-

Intelligent CNC control integration

These systems rely on a stable mechanical foundation to achieve their designed accuracy levels.

Production Advantages of Rigid Press Brake Frames

Manufacturers benefit directly from improved frame rigidity through:

-

Consistent bending accuracy across long parts

-

Reduced scrap and rework

-

Higher first-piece acceptance rate

-

Improved assembly consistency

-

Increased overall production efficiency

For precision fabrication, frame rigidity translates into measurable cost and quality advantages.

FAQ

What is press brake frame rigidity?

It refers to the ability of the press brake structure to resist deformation under bending load.

Why is frame rigidity important in a press brake?

Insufficient rigidity leads to bending angle inconsistency, reduced accuracy, and faster mechanical wear.

Can control systems compensate for poor frame rigidity?

No. Control systems can fine-tune motion but cannot fully correct structural deformation.

How does frame rigidity affect machine lifespan?

A rigid frame reduces fatigue stress and extends the service life of critical components.

Why Choose Alpha Press Brake Technology

Alpha specializes in press brake systems designed with high-rigidity welded frames, optimized structural geometry, and professional stress relief processing. Our machines provide a stable mechanical foundation for precision bending in demanding industrial environments.

Whether producing thick plates, long workpieces, or high-accuracy components, Alpha press brakes deliver structural reliability you can trust.

To learn more about Alpha press brake solutions or discuss your bending application requirements, please visit our Contact Us page.