Press Brake Backgauge Accuracy: The Key to Dimensional Consistency

In sheet metal bending operations, the backgauge system of a press brake directly determines flange length accuracy and overall part consistency. Even when bending angles are perfectly controlled, inaccurate backgauge positioning can result in dimensional deviation, assembly mismatch, and increased rework.

For manufacturers focused on precision fabrication and scalable production, press brake backgauge accuracy and repeatability are core performance indicators. Alpha designs press brake backgauge systems engineered to deliver stable positioning accuracy across long production cycles, multiple materials, and varying part geometries.

Why Backgauge Accuracy Matters in Press Brake Operations

The backgauge defines the reference position of the workpiece before bending. Any positioning error is directly transferred to the flange length and hole-to-bend distance.

Poor backgauge accuracy leads to:

-

Inconsistent flange dimensions

-

Difficulty in downstream assembly

-

Increased scrap and rework

-

Reduced production efficiency

In high-mix or batch production environments, repeatable backgauge positioning is essential to maintain consistent quality across all parts.

Technical Factors Affecting Press Brake Backgauge Accuracy

1. Linear Guide and Ball Screw Precision

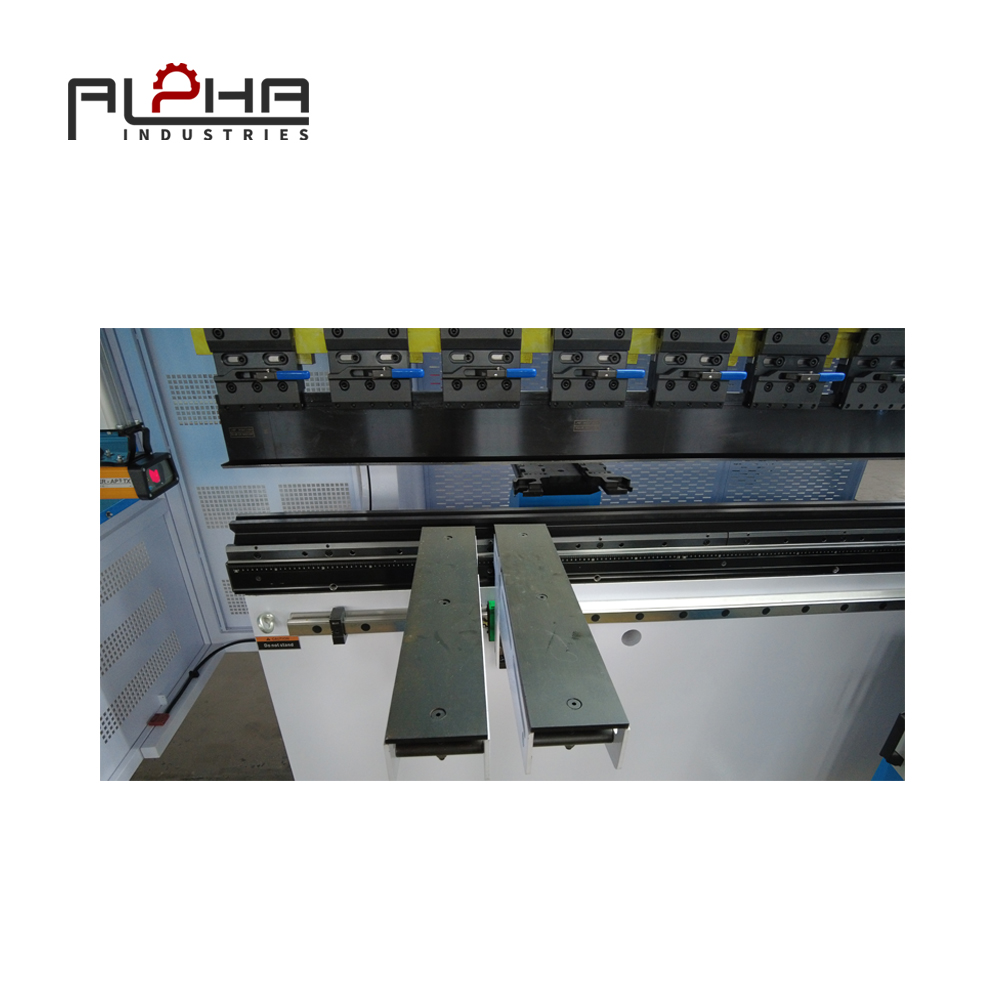

High-precision linear guides and ball screws ensure smooth and backlash-free movement of the backgauge fingers. Wear resistance and machining accuracy directly affect long-term positioning stability.

Alpha press brakes utilize precision-grade transmission components to maintain reliable backgauge accuracy under continuous operation.

2. Servo Drive and Motor Control

Modern press brake backgauge systems are typically driven by servo motors. Accurate servo control allows precise positioning, fast response, and stable repeatability.

Advanced servo-driven backgauges support:

-

High positioning resolution

-

Rapid positioning speed

-

Stable repeat accuracy during continuous cycles

3. Multi-Axis Backgauge Configuration

Complex sheet metal parts often require multiple reference points. Multi-axis backgauge systems (such as X, R, Z axes) allow flexible positioning for different bending sequences and part geometries.

Precise axis synchronization ensures that all backgauge fingers maintain consistent positioning relative to the bending line.

Repeatability: Long-Term Stability in Press Brake Production

Repeatability refers to the ability of a press brake to return to the same backgauge position consistently over time. Even small repeat errors can accumulate in batch production, leading to dimensional drift.

High repeatability is achieved through:

-

Rigid backgauge structure

-

Precision drive components

-

Stable servo control algorithms

-

Effective protection against dust and debris

Alpha press brake backgauge systems are engineered to maintain stable repeatability even in high-duty industrial environments.

Control System Integration and Intelligent Positioning

Modern press brake control systems integrate backgauge positioning with bending programs. The controller calculates backgauge positions automatically based on:

-

Material thickness

-

Flange length

-

Bending sequence

-

Tooling geometry

Intelligent control reduces manual setup, minimizes operator error, and ensures first-piece dimensional accuracy.

Benefits of High-Accuracy Backgauge Systems in Press Brakes

A well-designed press brake backgauge system delivers measurable production advantages:

-

Consistent flange dimensions across batches

-

Reduced setup time and manual adjustment

-

Improved downstream assembly accuracy

-

Higher overall production efficiency

-

Lower dependence on operator experience

For manufacturers producing cabinets, enclosures, frames, and precision structural components, these benefits are critical for maintaining competitive quality standards.

FAQ

What is a press brake backgauge used for?

The backgauge positions the workpiece accurately before bending, controlling flange length and dimensional consistency.

How accurate is a modern press brake backgauge?

With servo-driven systems and precision components, modern backgauges can achieve high positioning accuracy and repeatability suitable for precision fabrication.

Does backgauge accuracy affect bending angle?

Indirectly. While angle is controlled by ram depth, inaccurate backgauge positioning affects flange length and part geometry.

Is a multi-axis backgauge necessary?

For complex parts and flexible production, multi-axis backgauges significantly improve positioning flexibility and accuracy.

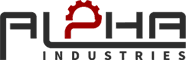

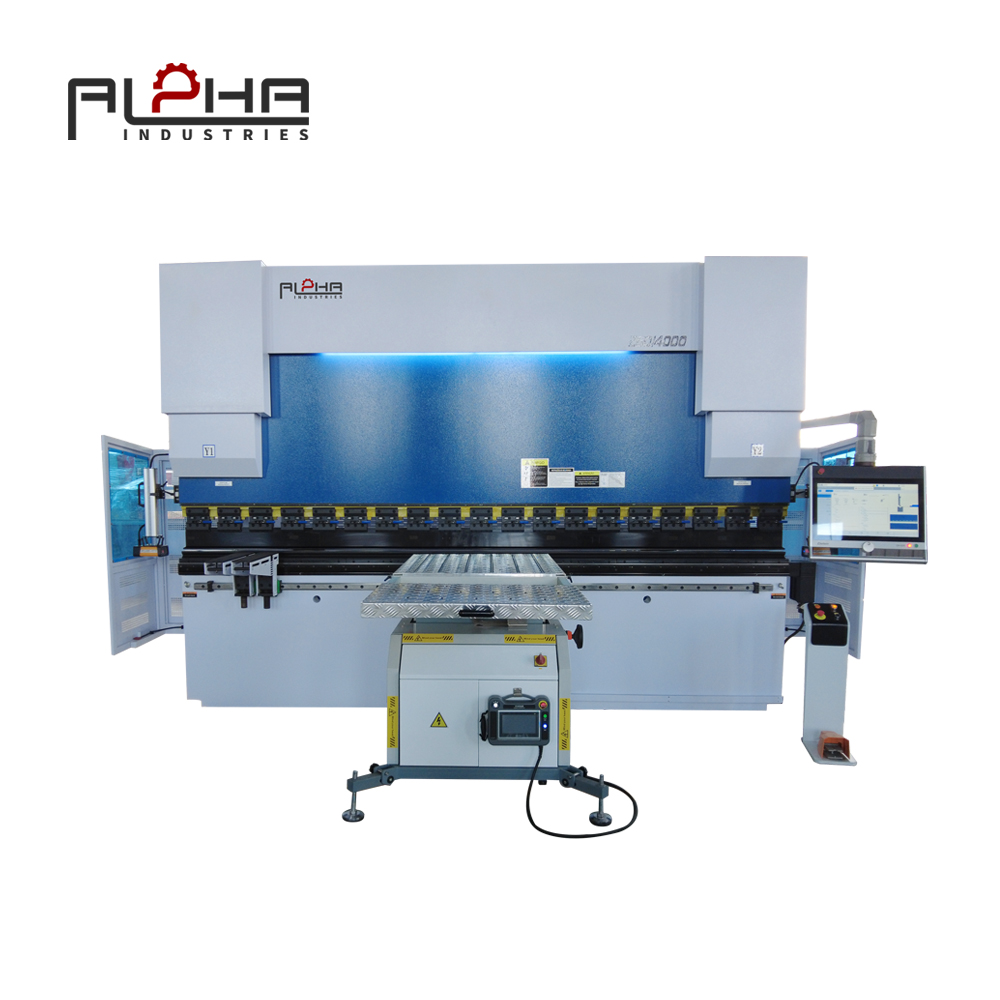

Why Choose Alpha Press Brake Solutions

Alpha specializes in press brake systems equipped with high-accuracy, servo-driven backgauge solutions. Our machines combine rigid structures, intelligent control systems, and reliable motion components to support precision sheet metal bending.

Whether your production involves custom fabrication or high-volume manufacturing, Alpha press brakes deliver the accuracy, repeatability, and stability required for professional metal forming operations.

To learn more about Alpha press brake solutions or discuss your bending requirements, please visit our Contact Us page.