Press Brake Angle Accuracy Control: A Core Factor in High-Quality Bending

In modern sheet metal fabrication, angle accuracy is one of the most critical performance indicators of a press brake. Even a small deviation of 0.5° can lead to assembly difficulties, increased rework, and material waste. For manufacturers pursuing consistent quality and scalable production, press brake angle accuracy control is not a secondary feature but a core technological capability.

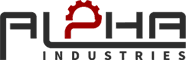

As a professional manufacturer, Alpha focuses on press brake systems engineered to deliver stable and repeatable bending angles across different materials, thicknesses, and batch sizes. This article analyzes press brake angle accuracy control from a technical perspective, explaining why it matters and how advanced press brake design directly improves forming results.

Why Angle Accuracy Matters in Press Brake Operations

Angle accuracy directly affects downstream processes such as welding, assembly, and surface finishing. Inaccurate bending angles cause cumulative dimensional errors, especially in complex sheet metal structures like cabinets, frames, and enclosures.

Key impacts of poor press brake angle accuracy include:

-

Increased scrap rate due to rejected parts

-

Manual angle correction and secondary bending operations

-

Inconsistent batch quality

-

Reduced production efficiency and higher labor cost

A high-performance press brake must maintain angle consistency not only on the first bend but throughout long production cycles.

Technical Factors Affecting Press Brake Angle Accuracy

1. Machine Frame Rigidity

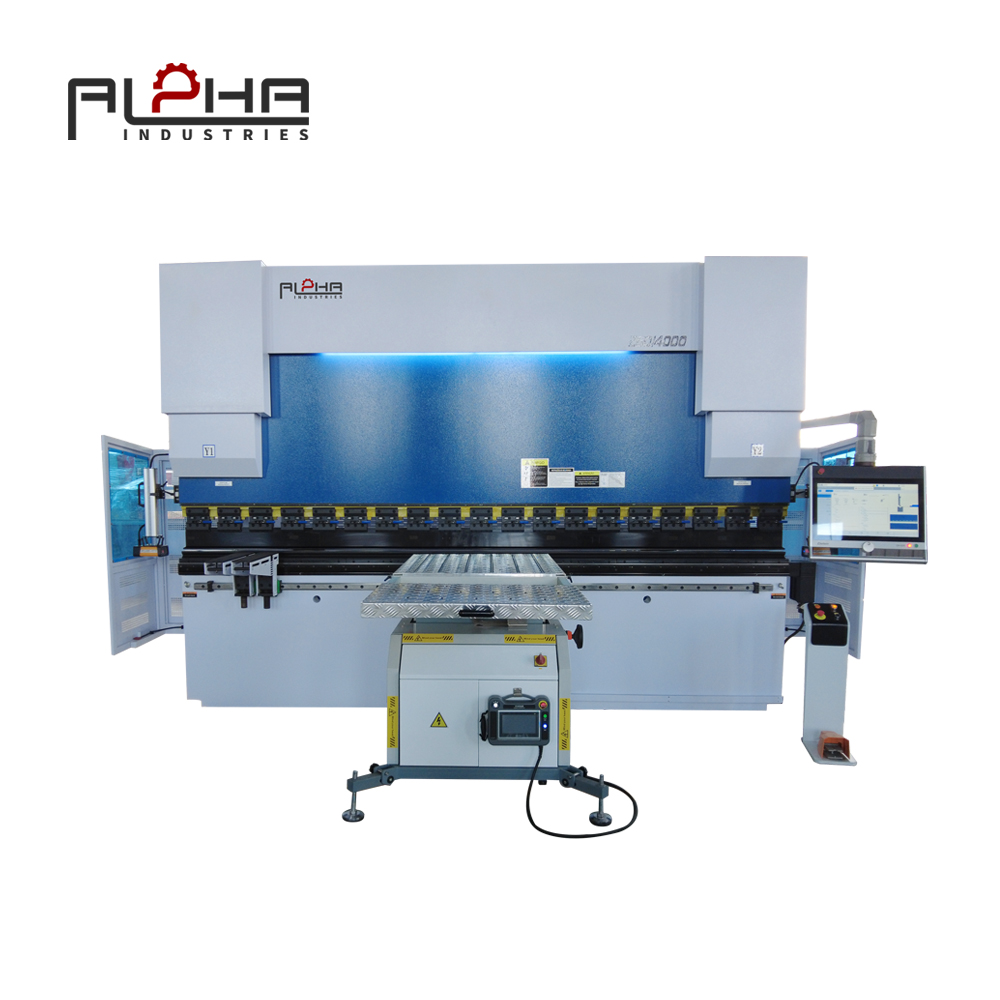

A rigid press brake frame minimizes elastic deformation under load. During bending, tonnage is unevenly distributed along the working length. Insufficient rigidity leads to center deflection, resulting in angle variation between the middle and edges of the workpiece.

Alpha press brakes utilize optimized frame structures with stress-relieved steel bodies, ensuring minimal deflection even under full-load bending conditions.

2. Ram and Backgauge Synchronization

Accurate synchronization between the ram movement and backgauge positioning is essential for repeatable angle results. Any deviation in axis movement directly affects bending depth and angle.

Advanced press brake control systems enable synchronized multi-axis control, maintaining precise ram positioning throughout the bending stroke.

3. Control System and Angle Calculation

Modern press brakes rely on intelligent control systems to calculate bending depth based on material thickness, tensile strength, tooling geometry, and target angle.

High-level press brake controllers support:

-

Automatic angle compensation

-

Material springback calculation

-

Real-time adjustment during bending

These functions significantly reduce operator dependency and improve first-piece accuracy.

Angle Compensation Technology in Press Brake Systems

Angle compensation is a key technology for achieving uniform bending results across the full working length of the press brake.

Mechanical and hydraulic compensation systems counteract frame deflection by applying controlled upward force during bending. This ensures consistent angle formation from left to right, even when bending long or thick sheets.

Alpha press brakes integrate precision compensation mechanisms that dynamically adjust according to bending force, enabling stable angle accuracy in both single-piece and mass production scenarios.

Tooling and Its Role in Press Brake Accuracy

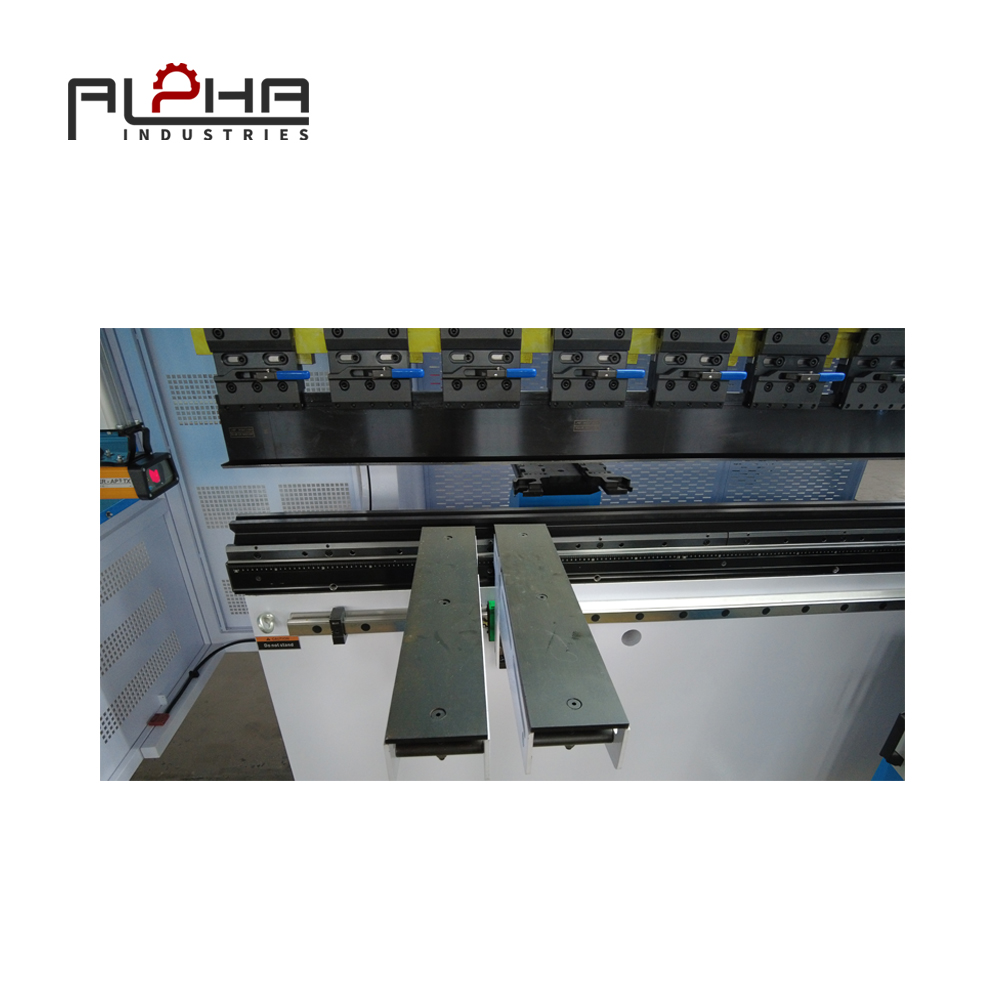

Press brake tooling quality has a direct impact on bending angle precision. Factors include:

-

Punch and die angle consistency

-

Tool surface finish

-

Tool alignment and clamping stability

Precision-ground press brake tooling reduces friction and deformation, ensuring predictable material flow during bending. Proper tooling selection, combined with accurate machine calibration, allows press brakes to achieve repeatable angles across different applications.

FAQ

How does a press brake maintain accurate bending angles?

A press brake maintains angle accuracy through rigid frame design, synchronized axis control, intelligent control systems, and compensation technology that offsets deflection and material springback.

Does material type affect press brake angle accuracy?

Yes. Different materials have varying tensile strength and springback characteristics. Advanced press brake controllers adjust bending depth automatically based on material parameters.

Can a press brake achieve consistent angles in long workpieces?

With proper compensation systems and rigid frame construction, a press brake can maintain uniform angles along the entire bending length.

Is angle accuracy dependent on operator experience?

Modern press brakes reduce operator dependency by using automated angle calculation and compensation, ensuring stable results even with less manual intervention.

Why Choose Alpha Press Brake Solutions

Alpha specializes in press brake systems designed for high-precision angle control in demanding industrial environments. Our machines combine rigid structural design, advanced control systems, and reliable compensation technology to support consistent, high-quality sheet metal bending.

Whether you are producing small batches or large-scale industrial components, Alpha press brakes deliver the accuracy and stability required for professional metal forming operations.

To learn more about Alpha press brake solutions or discuss your bending requirements, visit our Contact Us page.