Why Thermal Stability Matters in Milling Machines

In industrial machining environments, milling accuracy is not only influenced by mechanical rigidity and control systems. Thermal behavior plays an equally decisive role. During extended milling operations, heat generated by spindle rotation, cutting forces, motor systems, and ambient temperature variation can cause structural expansion. If unmanaged, thermal deformation becomes one of the primary sources of dimensional error in milling machines.

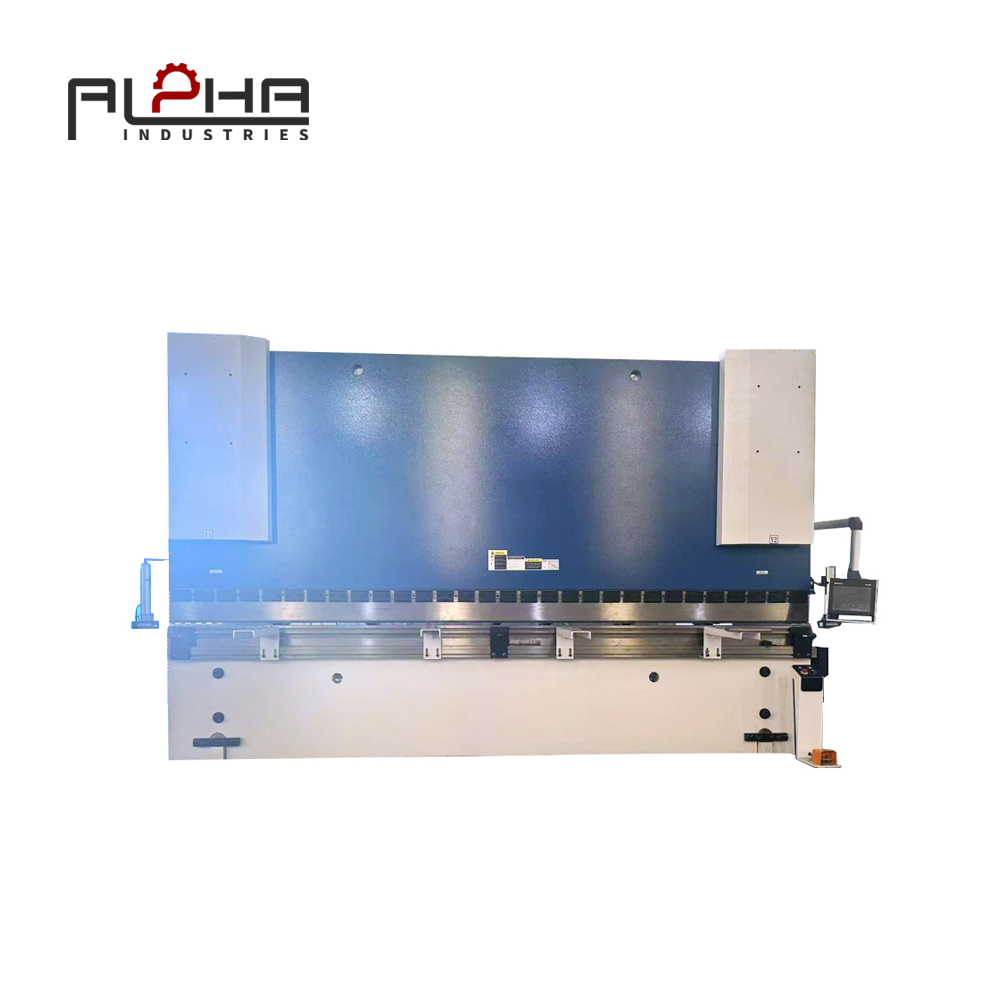

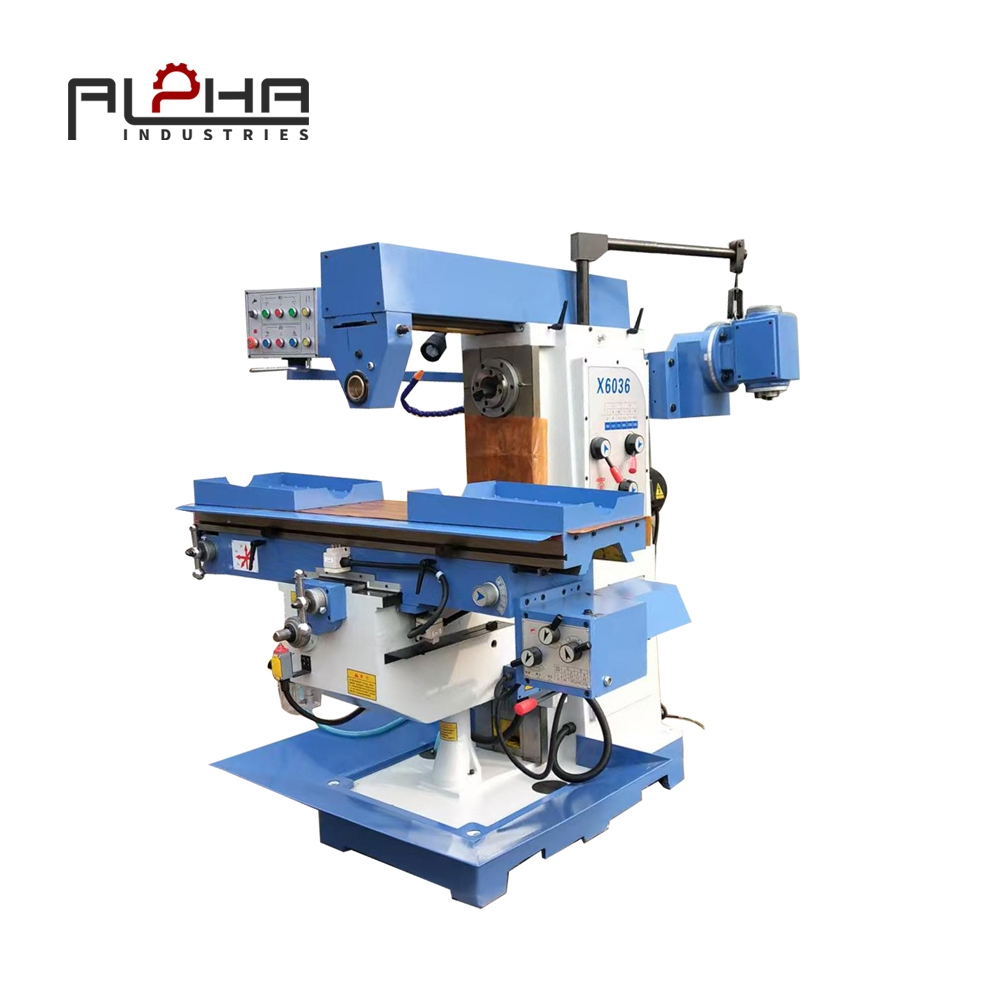

For manufacturers requiring long-term precision and repeatable results, milling machine thermal stability is the hidden factor that separates precision-grade equipment from conventional machines. At Alpha, thermal stability is engineered into every milling machine from the earliest design stage.

Understanding Milling Machine Thermal Stability

Thermal stability refers to a milling machine’s ability to maintain geometric accuracy despite internal and external temperature changes. As temperature fluctuates, machine components such as the spindle, column, bed, and guideways expand at different rates. Uneven thermal expansion directly affects positioning accuracy, tool alignment, and surface quality.

A thermally stable milling machine ensures:

-

Consistent axis positioning over long machining cycles

-

Minimal thermal drift of the spindle centerline

-

Stable cutting conditions during continuous operation

-

Predictable dimensional results across multiple shifts

Heat Sources in Milling Machine Operation

Spindle and Drive System Heat

High-speed spindle rotation generates frictional heat within bearings and motor assemblies. Without effective thermal control, spindle elongation alters tool position, resulting in depth-of-cut variation and tolerance deviation.

Cutting Process Heat

During heavy material removal, cutting energy converts directly into heat at the tool-workpiece interface. This heat transfers into the spindle nose, tool holder, and workpiece, influencing machining accuracy.

Environmental Temperature Influence

Ambient workshop temperature changes between day and night shifts can introduce slow but significant structural deformation in large milling machines.

Structural Design for Thermal Balance in Milling Machines

Symmetrical Machine Structure

Alpha milling machines utilize symmetrical structural layouts to ensure uniform thermal expansion. By balancing heat flow paths, thermal distortion is evenly distributed, preventing localized deformation that affects machining accuracy.

High-Quality Cast Iron with Thermal Inertia

High-density cast iron components provide strong thermal inertia, slowing temperature change and stabilizing the machine structure. This allows the milling machine to maintain accuracy during prolonged operation periods.

Spindle Thermal Control Technology

Precision Bearing Configuration

Optimized bearing preload reduces frictional heat generation while maintaining spindle stiffness. This balance is essential for both thermal stability and cutting performance.

Active Cooling Systems

Spindle cooling channels and temperature-regulated coolant circulation maintain stable spindle temperature, minimizing axial growth and radial displacement.

Guideway and Ball Screw Thermal Compensation

Linear guideways and ball screws are sensitive to thermal expansion. Alpha milling machines apply controlled lubrication and optimized installation geometry to reduce thermal-induced positioning errors. In advanced configurations, thermal compensation algorithms adjust axis positioning in real time.

How Thermal Stability Improves Milling Accuracy

Thermally stable milling machines deliver measurable benefits:

-

Dimensional Accuracy: Reduced thermal drift ensures tight tolerance control over long production cycles.

-

Surface Finish Consistency: Stable tool position prevents waviness caused by thermal growth.

-

Repeatability: Identical machining results across shifts and production batches.

-

Reduced Scrap Rate: Predictable machining minimizes part rejection due to dimensional variation.

These advantages are essential for precision manufacturing sectors such as automotive components, mold making, and mechanical parts production.

Application Scenarios Requiring High Thermal Stability Milling Machines

Thermal stability is critical in:

-

Long-cycle milling operations

-

High-precision finishing processes

-

Large workpiece machining

-

Multi-shift continuous production

-

Tight tolerance batch manufacturing

Alpha milling machines are engineered to perform reliably under these demanding conditions.

Alpha Milling Machine Thermal Engineering Philosophy

At Alpha, thermal stability is treated as a system-level engineering objective. From material selection and structural layout to spindle cooling and assembly accuracy, every design decision contributes to controlled thermal behavior. This ensures Alpha milling machines maintain precision not just at startup, but throughout extended production cycles.

FAQs

What causes thermal deformation in a milling machine?

Thermal deformation is caused by heat from spindle rotation, cutting processes, drive systems, and ambient temperature changes.

Why is thermal stability important for precision milling?

Without thermal stability, machine expansion leads to dimensional drift and inconsistent machining accuracy.

How do milling machines control thermal effects?

Through symmetrical structure design, high thermal inertia materials, spindle cooling systems, and thermal compensation strategies.

Is thermal stability more important for large milling machines?

Yes. Larger structures are more sensitive to temperature gradients, making thermal control essential.

Conclusion: Thermal Stability Determines Milling Machine Reliability

Thermal stability is a defining factor in milling machine accuracy, efficiency, and reliability. By controlling thermal behavior, manufacturers can achieve consistent quality, reduced scrap, and predictable performance over long production cycles.

Alpha is committed to delivering milling machines engineered for thermal stability and long-term precision, supporting real-world industrial manufacturing demands.

👉 Learn more about our milling solutions or Contact Us to discuss your application requirements.